Surfing on leaves and coffee bags with Greenhouse Surf

Intro and questions by: Tyler Fox / Answers by: Ken Cole and Ted Burdett

When I first saw the IG post on @greenhousesurf proclaiming “The first wave EVER ridden on a surfboard made of leaves happened today, October 14th, 2024, in Sheboygan, Wisconsin on Lake Michigan!” I was both elated and, to be honest, a little apprehensive about the truth behind this bold claim. After chatting more over a virtual meeting, that apprehension subsided, but I still have plenty of questions for you guys, and I’m sure our followers do too. That said, let’s jump into it!

Q1: What the heck have you two created, and how do you know with such certainty this type of construction and materials are the first of their kind in a surfboard?

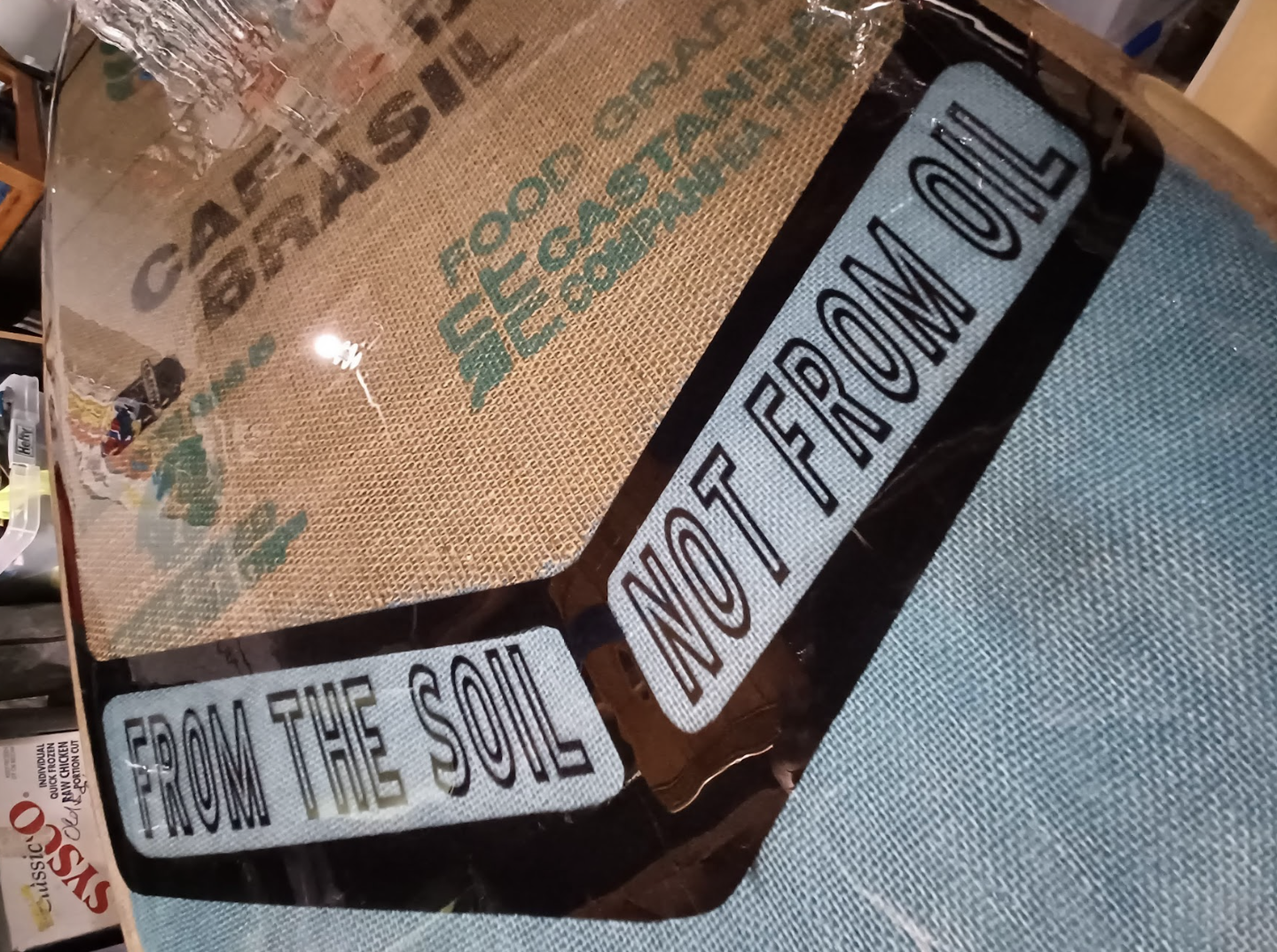

In essence, the first board is made from the components of palm leaf, jute, and plant-based resin. Your initial apprehension is well understood and, in many respects, warranted. However, those are the three parts that were used to make our prototype. My confidence in this being the first “EVER” stems from feedback gleaned from my patent application and seeing no other reference via patent applications, or a fairly wide and comprehensive web search (and yes, social media) that this has not been done before. Engaging with folks who are leaders in sustainability also reveals that there is nothing else like this out there. This ranges from Wavechanger, WSL One Ocean, and yes, Sustainable Surf. The latter of which are the preeminent gold standard on sustainability.

Q2: What brought you guys together to create this unique project?

We’d followed each other for some time on Instagram through @Greenhousesurf. I don’t recall the exact date, but Ted reached out via messenger inquiring about the Great Lakes Surf Project that his team was working on. Initially, the focus was on my efforts with using more sustainable materials, but he recalled my vision to create one solely out of leaves. Our conversation continued, and he shared more about his work as a designer, but also as someone familiar with processes that could lead us toward the creation of a workable prototype.

Q3: What exactly are the materials being used?

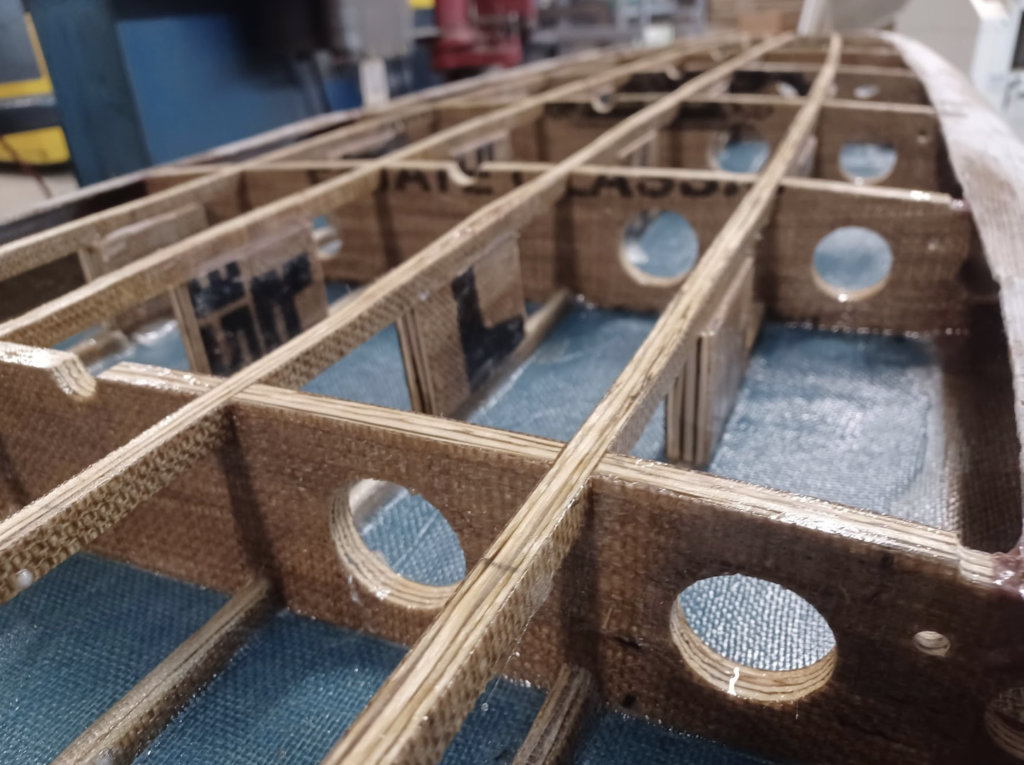

Basically, there are three materials: jute, palm leaf, and plant-based resin. That’s pretty much it. For the prototype, as shared during our conversation, there is repurposed balsa at the nose and tail, and it is wrapped with Volan cloth. The latter was added just for the prototype. Future iterations can be made with just jute, palm leaf, and plant-based resin.

Q4: How labor-intensive is the process to make one of these boards, and do you think it could have mass adoption? Either to the board builder or to consumers?

With any product, the first one is going to take the most time. This, coupled with the fact that there were no subject matter experts on this, except for Ted and me, meant that we had to start from scratch, while also leveraging the skills and resources we collectively possessed to bring it together. Future boards would take much less time as the designs for the internal truss structure are saved and can be modified as needed. It should also be known that between my shop and Ted’s, we had ample ability to fabricate the deck and belly. However, when compared to larger-scale operations, the ease of replication of what we’re doing would likely result in a faster turnaround and an even more refined board.

Regarding mass adoption, that’s the point of it all, isn’t it? We can continue to go down the EPS path that is simply unsustainable, literally. Or we can do deeper dives into what innovators in sustainability in surfboard design (and design in general) are doing and “push the limits.” So yes, if an average surfer/shaper in Milwaukee can work with a designer in Michigan and not only make a fully functional surfboard out of leaves and surf it, a larger commitment would begin to help us understand the potential for mass adoption.

And as the realities of climate change become undeniable, there will slowly be a need for a sustainable option. The surf industry, above all else, is long overdue for such a shift. This hypocrisy that is rampant, of which I’m a part because of my own quiver, is without question something that millions of surfers want to move past. We love our oceans and lakes more than most, yet the very craft we use to celebrate the waters we ride in also contribute to their slow degradation.

Q5: Even though the resin you are using is plant-based, you probably couldn’t just throw this into your compost pile and expect it to biodegrade, right?

Definitely not something that’s going into the compost pile. And thankfully, even with my bold proclamations, one that was never made was that it would biodegrade and complete a natural life cycle. But from a footprint standpoint, drain on resources, and even the energy it took to create the board, I would put our board against any on the market and am confident the full life cycle is much closer to sustainability.

Q6: How many sessions have you had on this initial prototype, and how does it compare to a traditional foam core surfboard?

I’ve had one amazing session that was the board’s inaugural ride. I prepped and claimed that the day the board caught its first wave would be a Kitty Hawk moment for surfing. One session, and one of the first things that stood out was the hollow sound, as well as the ease of paddling. The sound was new to me, as it was the first hollow board I’ve ever ridden. Float was good, and it caught the wave rather easily. What surprised me was that it turned just like all my other single-fin pigs. The biggest difference is likely weight, obviously, as we’ve replaced the EPS core that is on millions (and far too many) boards and replaced it with an internal truss structure made of the composite made of the three components mentioned earlier. In my quiver, I have an early 60’s Jacobs D-fin, and I’d compare the weight to an old-school longboard. But as referenced above, as a prototype, future iterations would refine both compositing and determine how best to lower weight while also maximizing strength and performance.

Q7: We just got news of a whiz kid named Charlie Cadin over in Europe who has developed a surfboard sealing process using just beeswax… no resin at all, and he says it can biodegrade in about a month! Shall I put you guys in touch with him?

Without question, make the connection! We’ve already exchanged pleasantries on IG following his announcement of the resin. My comment to him was that the resin is the only remaining piece to getting to a “close to” truly sustainable surfboard.

Q8: Any last words you’d like to share with our followers, and where can people follow your groundbreaking journey?

By all means, they can follow us at @greenhousesurf. Full disclosure, my full-time gig is as a psychologist, so the updates are not daily, but as evidenced by what we’ve created, they are ongoing and moving forward. As far as “words of wisdom,” it’s just that what we’ve done, what Charlie’s done, should not be simple human interest stories, or viewing these efforts as quirky or one-offs. Instead, they should inspire industry leaders to step their game up and do a deep dive into true sustainability. I know enough about climate change, but also a business’ “bottom line,” and realize that eventually, they will get to a place where the need for sustainable alternatives is not just an option, but it becomes the norm. One need only look at the rapid growth of electric cars, wind farms, solar power, and the increased banning of EPS across the globe to realize surfing is a couple of steps behind. Let’s have our love for the oceans and the planet compel us to be the leaders and inspire others to follow us.